COOLING WATER TREATMENT

We understand that the water treatment of cooling towers is an integral part of process operations in many industries, with the possibility of productivity and product quality being adversely affected by scale, corrosion, fouling and microbiological contamination.

We understand that the water treatment of cooling towers is an integral part of process operations in many industries, with the possibility of productivity and product quality being adversely affected by scale, corrosion, fouling and microbiological contamination.

These water treatment problems can be very costly when they cause the loss of heat transfer in the cooling tower, equipment failure, and health and safety concerns. VASU-NORTHMAN uses a unique engineering approach, looking at your cooling tower and water treatment systems from mechanical, operational and chemical angles.

We can provide best-in-class cooling tower water treatment solutions tailored to your cooling tower systems.

BOILER WATER TREATMENT

Northman starts water treatment with boiler water treatment, and more than 15 years ago, we began treating boilers for industry. And that long-term commitment to developing the most innovative boiler water treatment technologies in the industry continues today. It is a result of our desire to improve your competitive advantage and decrease your total operating costs.

Northman starts water treatment with boiler water treatment, and more than 15 years ago, we began treating boilers for industry. And that long-term commitment to developing the most innovative boiler water treatment technologies in the industry continues today. It is a result of our desire to improve your competitive advantage and decrease your total operating costs.

A single day of lost steam production can cost you much more than the cost for one or two years of our boiler water treatment programs. While our program costs may not significantly impact your bottom line, we understand that our results do, and we are passionate about helping you produce reliable, safe, and cost-effective steam. Successful boiler operation requires a total system approach to:

- Prepare feed water before it goes to the boiler

- Protect and keep the internal boiler surfaces clean

- Maximize condensate return

We can perform detailed system audits and diagnostics in association with our principals who are leaders in water and steam to prescribe the best chemical, steam distribution and service programs to maximize your boiler system performance and efficiency through an effective boiler water treatment program. Through utilizing our innovative programs, we can help you achieve water and energy savings, asset preservation, and increased plant reliability and safety.

POLYELECTROLYTE ŌĆō WASTE WATER TREATMENT

VASU-NORTHMAN understands that effective primary waste water treatment is critical to your plant operations, whether you are discharging directly to a municipal wastewater treatment system or treating prior to your own biological wastewater treatment system. Optimizing the performance of treatment chemicals and equipment can dramatically minimize overall costs and maximize your return on investment, and we can provide creative solutions to help meet your most stringent water quality requirements.

VASU-NORTHMAN understands that effective primary waste water treatment is critical to your plant operations, whether you are discharging directly to a municipal wastewater treatment system or treating prior to your own biological wastewater treatment system. Optimizing the performance of treatment chemicals and equipment can dramatically minimize overall costs and maximize your return on investment, and we can provide creative solutions to help meet your most stringent water quality requirements.

Solids dewatering is the second-highest cost area in a wastewater treatment plant, second only to electrical utility costs. Effectively optimizing the performance of dewatering equipment and chemicals can dramatically minimize the total cost of operation and maximize your return on investment. In addition, as processors endeavour to meet stringent regulatory requirements, solids handling and disposal continues to be one of the most important areas requiring creative, sustainable-technology solutions.

We also understand that effective secondary wastewater treatment is critical to your plant operations. We can provide you with creative treatment chemicals and equipment solutions, helping you meet your most stringent water quality requirements and maximize your return on investment. Our programs typically focus on the following and can help you with:

- Improving overall plant economics

- Increasing operator capabilities and effectiveness

AHU / AC COIL CLEANING

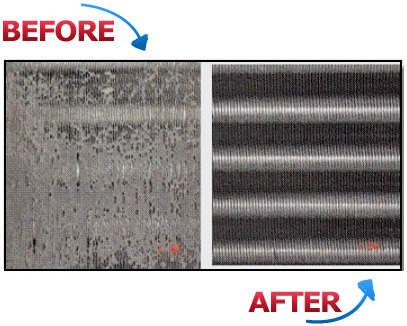

Answering questions about how to clean A/C evaporator coils usually begins with why to clean them in the first place. The evaporator coil in your air conditioner is ground zero of the cooling process that keeps your work place comfortable throughout these long Louisiana summers. Cooling a house is all a matter of moving indoor heat energy outside. Installed inside the indoor air handler, the evaporator coil circulates refrigerant that absorbs heat from household air circulating through the ducts and conveys it to the condenser coil outside where itŌĆÖs dispersed into the air.

Answering questions about how to clean A/C evaporator coils usually begins with why to clean them in the first place. The evaporator coil in your air conditioner is ground zero of the cooling process that keeps your work place comfortable throughout these long Louisiana summers. Cooling a house is all a matter of moving indoor heat energy outside. Installed inside the indoor air handler, the evaporator coil circulates refrigerant that absorbs heat from household air circulating through the ducts and conveys it to the condenser coil outside where itŌĆÖs dispersed into the air.

Taking out the heat

The heat extraction process that takes place at the evaporator coil relies on a precise amount of refrigerant vapour flowing through the coil and clean coil surfaces to facilitate the efficient absorption of heat energy into the refrigerant. As these surfaces become coated with dust or the small air passages that allow air to pass through the coil are obstructed, the effectiveness of the heat transfer process begins to decline proportionately. The direct impact is on your

ELECTRICITY BILLS.

ItŌĆÖs the humidity, too

Your work place cooling equipment is called an air conditioner instead of an air cooler because removing humidity from indoor air is an equally vital function of the evaporator coil. Moisture in the air holds heat and makes living spaces harder to cool. Conditioned air at low humidity levels cools more effectively and feels more comfortable. A dirty coil also underperforms as a humidity extractor, leaving rooms clammy and making cooling less effective.

To do it yourself

Coil cleaning chemical ŌĆō VANIKLIN-WB is user friendly innovative approach for cleaning AHU / AC coils. By using any spray pump, you can clean coils which will not only increase cooling but also ensure control on your electricity bills.

RO ANTI SCALANTS

SPECTRAGUARD chemical "scale inhibitors," prevent mineral deposits from building on your membrane, causing fouling. Our VASU-PWT product line helps resolve these problems-and in almost every instance, at a lower cost than it would be to use ion exchange to remove hardness.

SPECTRAGUARD chemical "scale inhibitors," prevent mineral deposits from building on your membrane, causing fouling. Our VASU-PWT product line helps resolve these problems-and in almost every instance, at a lower cost than it would be to use ion exchange to remove hardness.

RO MEMBRANE CLEANING

When a membrane does need cleaning, our VASU-PWT chemical product line removes most foulants and restores performance in all types of membrane systems. We can provide you cleaning chemicals specifically formulated to remove mineral scale, insoluble scale, organic fouling or microbial residue.

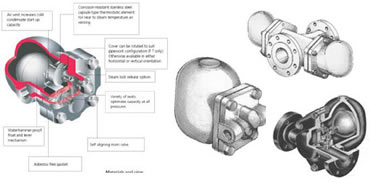

THERMODYNAMIC STEAM TRAP

Thermodynamic steam trap with inbuilt strainer and full stainless steel construction, best suited for header and mainline drains and drop legs.

Thermodynamic steam trap with inbuilt strainer and full stainless steel construction, best suited for header and mainline drains and drop legs.

The TD-3 Thermodynamic Steam Trap is suitable for draining main steam distribution lines where prompt removal of condensate is essential. The TD-3 uses the velocity and phase change of pressurised condensate flashing to lower pressure steam to operate the disc. Its hardened seat and disc and absence of moving parts ensures a long service life. Although the trap operates in any position, horizontal orientation is preferred.

BALL FLOAT STEAM TRAPS

Float Traps is the best choice for process applications. The only ball float steam trap with over 50 years of experience and constant development

Float Traps is the best choice for process applications. The only ball float steam trap with over 50 years of experience and constant development

The FORBES Marshall Ball Float Trap (FT) is the product of experience. First launched in the 1940's the F 1 has become the most advanced ball float steam trap available. Constant design improvements have "ace today's FT an extremely robust steal trap. Ideally suited to the NgoroŌĆÖs demands of any steam system. Unique amongst all pail float steam traps is the self aligning main valve, water hammer proof float assembly and corrosion resistant air vent Such attention to detail ensures complete shut-off at all pressures and reliable operations which lead to an extended product life and minimal maintenance. Having an integral thermostatic air vent and options of a steam Sock release (SIR) and drain cock tapping, the FT range is adaptable to all applications where ball float traps are recommended and instantaneous removal of condensate is required.

W'th over 3 mllion FORBES Marshall float traps supplied to over 15000 customers the Sptrax Marshal F 1 has become the most widely used ball float steam trap in the world today.

AUTOMATIC PUMPING TRAP

FORBES Marshall brings to you the Automatic Pumping Trap - the world's smallest condensate drainage system that works under all the load conditions, even vacuum. It's compact design makes it convenient to install within 200 mm of the installation head. The Automatic Pumping Trap is fully mechanical with no requirement for electrical power, pnuematic supply, motors or level switches.

FORBES Marshall brings to you the Automatic Pumping Trap - the world's smallest condensate drainage system that works under all the load conditions, even vacuum. It's compact design makes it convenient to install within 200 mm of the installation head. The Automatic Pumping Trap is fully mechanical with no requirement for electrical power, pnuematic supply, motors or level switches.

What do you mean by Stall ?

Stall is the reduction or the cessation of condensate flow from the steam space, and occurs when the pressure in the steam space is equal to, or less than, the total backpressure imposed on the steam trap.

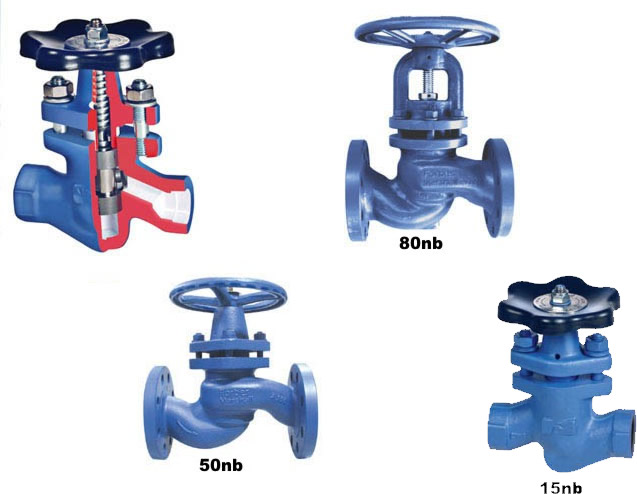

PISTON VALVE

FM PISTON VALVE is a zero leak isolation Piston Valve, in which the seat & gland are replaced by Lower & Upper Sealing rings along with a Piston. This overcomes the difficulties usually associated with the replacement of conventional seats.

FM PISTON VALVE is a zero leak isolation Piston Valve, in which the seat & gland are replaced by Lower & Upper Sealing rings along with a Piston. This overcomes the difficulties usually associated with the replacement of conventional seats.

The FM Piston valve is the name for prevention of inline leakage as well as leakage through glands, making for leakproof isolation in the pipelines.

The FM Piston valve is a seat less & gland less Piston Valve. At the heart of the FM piston valve are Piston & sealing rings. A burnished piston seals against SS reinforced graphite rings to achieve a leak proof shutoff. This unique design ensures a long life even at high temperatures up to 427 deg C

A Burnished piston is connected to the Piston Valve stem & hand wheel. The piston passes through two sealing rings separated by a lantern bush. Each sealing ring is Stainless steel reinforced graphite, which has both features of sustaining compression exerted by Bonnet & providing soft seal against piston. The upper sealing ring acts as a conventional gland packing and prevents leakage towards atmosphere. The lower sealing ring acts as the seat which prevents in line leakage. The lantern bush is required to maintain separation between the upper & lower rings & to allow flow through the Piston Valve.

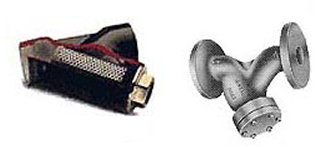

DISC CHECK VALVES

FORBES Disc Check Valves are recommended after traps discharging into closed systems to guarantee against return or spill back. DCVs feature a compact and rugged stainless steel design and are suitable for any process liquid & gas, not just steam. Main advantage of these check valves is they can be mounted between pipe flanges in any direction.

FORBES Disc Check Valves are recommended after traps discharging into closed systems to guarantee against return or spill back. DCVs feature a compact and rugged stainless steel design and are suitable for any process liquid & gas, not just steam. Main advantage of these check valves is they can be mounted between pipe flanges in any direction.

DCV 1,2,3

DCV 1, 2 and 3 Disc Check Valves are designed to be sandwiched between flanges i.e. wafer type. They are suitable for use on a wide range of fluids for applications in process lines, hot water systems, steam and condensate systems etc.

DCV 4 Wafer Check Valve

The DCV 4 Disc Check Valve is designed to be sandwiched between ANSI flanges. It is suitable for use on a wide range of fluids for applications in process lines, hot water systems, steam and condensate systems etc.

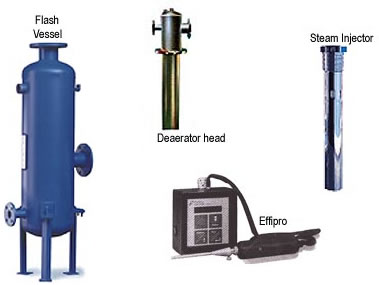

Condensate Flash Vessel

Flash steam can be effectively recovered by using a Condensate Flash Vessel as a part of a Flash Steam Recovery System. The flash steam is free steam and can be used to supplement the normal steam requirement. Flash steam should be separated from the condensate to maximise the system''s efficiency. Since the flash steam is utilised, it will not be vented to the atmosphere where it is wasted and can be a safety hazard.

Flash steam can be effectively recovered by using a Condensate Flash Vessel as a part of a Flash Steam Recovery System. The flash steam is free steam and can be used to supplement the normal steam requirement. Flash steam should be separated from the condensate to maximise the system''s efficiency. Since the flash steam is utilised, it will not be vented to the atmosphere where it is wasted and can be a safety hazard.

Condensate Recovery Pump

Hot condensate still contains 20% of the energy you used to make steam in the first place. And since condensate is distilled water, it makes perfect boiler feedwater. Our positive displacement pressure Powered Pump is the heart of a money and energy saving Condensate Return System.The PPPU pumps condensate at 100 oC without electricity, using just a small blast of steam or air pressure, even under vacuum and stall conditions. Due to its sealed & gland-less design, the collected condensate can be pumped immediately, without waiting for it to cool, and with no risk of cavitation

Hot condensate still contains 20% of the energy you used to make steam in the first place. And since condensate is distilled water, it makes perfect boiler feedwater. Our positive displacement pressure Powered Pump is the heart of a money and energy saving Condensate Return System.The PPPU pumps condensate at 100 oC without electricity, using just a small blast of steam or air pressure, even under vacuum and stall conditions. Due to its sealed & gland-less design, the collected condensate can be pumped immediately, without waiting for it to cool, and with no risk of cavitation

Pressure Powered Pumping Packaged Unit (PPPPU)

Pressure Powered Pumping Packaged Unit is a positive displacement pump unit operated by steam, compressed air or pressurized gas. The unit is specifically designed to pump hot liquids of specific gravity 1.0 down to 0.9.

Condensate Recovery (CRM) is also an integral part of the PPPPU. It is an effective management tool which not only shows the condensate quantity & condensate temperature, but also shows the energy saved through condensate return.

Together, this unit is a complete solution to collect condensate, pump it to desired level and destination, to measure the condensate temperature and meter the condensate quantity. PPPPU has to be preceded with properly sized flash vessel depending upon the condensate parameters.

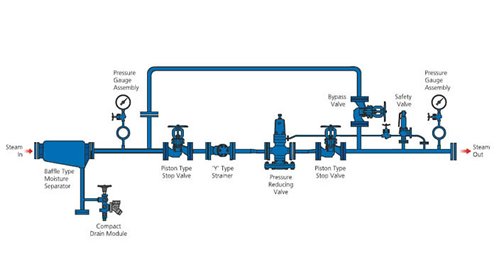

PRESSURE REDUCING STATION

The FORBES pressure reducing station is an engineered and factory assembled unit. It is designed in line with good steam engineering practices using our proprietary software. FORBES Marshall manufactures all the components of the pressure reducing station in-house, which enables quality control for each component to FORBES standards. Every component is tested on live steam & the entire assembly is hydro tested.

The FORBES pressure reducing station is an engineered and factory assembled unit. It is designed in line with good steam engineering practices using our proprietary software. FORBES Marshall manufactures all the components of the pressure reducing station in-house, which enables quality control for each component to FORBES standards. Every component is tested on live steam & the entire assembly is hydro tested.

Deaerator Head

Fitted on your feedtank, the FORBES Deaerator Head mixes cold make-up water, hot condensate, and flash steam in a single stainless steel (SS) head to get the most out of your captured heat.Cold make-up water atomizes in the mixing head releasing 90% of dissolved oxygen, a primary source of downstream corrosion. The single head design eliminates the need for cumbersome spurge pipes.

Fitted on your feedtank, the FORBES Deaerator Head mixes cold make-up water, hot condensate, and flash steam in a single stainless steel (SS) head to get the most out of your captured heat.Cold make-up water atomizes in the mixing head releasing 90% of dissolved oxygen, a primary source of downstream corrosion. The single head design eliminates the need for cumbersome spurge pipes.

STRAINERS

One FORBES Strainer upstream of every trap, control valve, and flowmeter can save you a bundle in annual maintenance and wear & tear costs. Available in Y or T type designs, our Strainers remove suspended grit from steam and condensate that would otherwise damage your downstream equipments with no additional pressure drop.

One FORBES Strainer upstream of every trap, control valve, and flowmeter can save you a bundle in annual maintenance and wear & tear costs. Available in Y or T type designs, our Strainers remove suspended grit from steam and condensate that would otherwise damage your downstream equipments with no additional pressure drop.

FIG 12 Strainer

The FIG 12 Y-type Strainers with stainless steel screens have 0.8 mm diameter perforations as standard.

Available sizes and pipe connections:

15 NB, 20 NB and 25 NB Screwed BSPT/NPT

40 NB & 50 NB Screwed BSPT/NPT

FIG 14 Strainer

The FIG 14 Strainer is available in the following sizes : 25 NB, 40 NB & 50 NB

FIG 32 Strainer

FIG 32 Strainers are available in cast iron/cast steel with stainless steel screen and have 0.8 mm diameter perforations as standard.

Available sizes and pipe connections:

Cast Iron FIG 32 Strainer - NB 40, 50, 80,100, 150 & 200. Flanged

Cast Steel FIG 32 Strainer - NB 40, 50, 80, 100. Flanged